Understanding Corporation Stop Requirements

Understanding Corporation Stop Requirements

The corporation stop is the initial control valve of the service line as it is the first valve off of the main. The sole purpose is to allow for the installation of a new water service line without interrupting the water main pressure. The corporation stop is usually only used once as a last resort options as it temporarily shuts off water while the service line is connected to the curb stop.

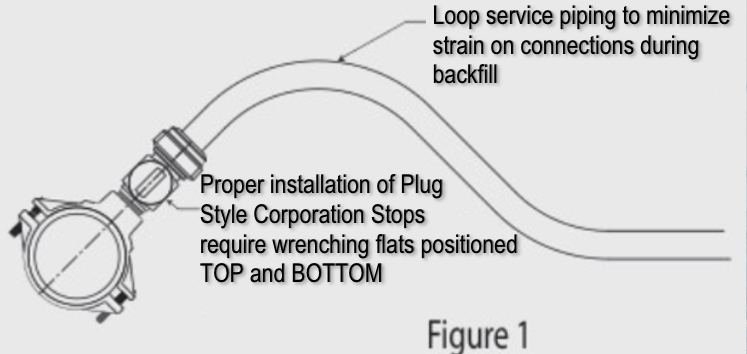

The basic installation of a corporation stop should include the use of a smooth jawed adjustable wrench on the flats nearest the inlet threads. This is because serrated pipe wrenches offer a loose fit that can distort the body and cause a leak. The corporation stop can be ball or plug. Plug styles should be installed so that the wrenching flats of a tightened valve are positioned top and bottom. Backfill carefully to avoid damage to the corporation stop, the service line, and the connections. Loop service piping on corporation connections to minimize the strain on the body and connections.

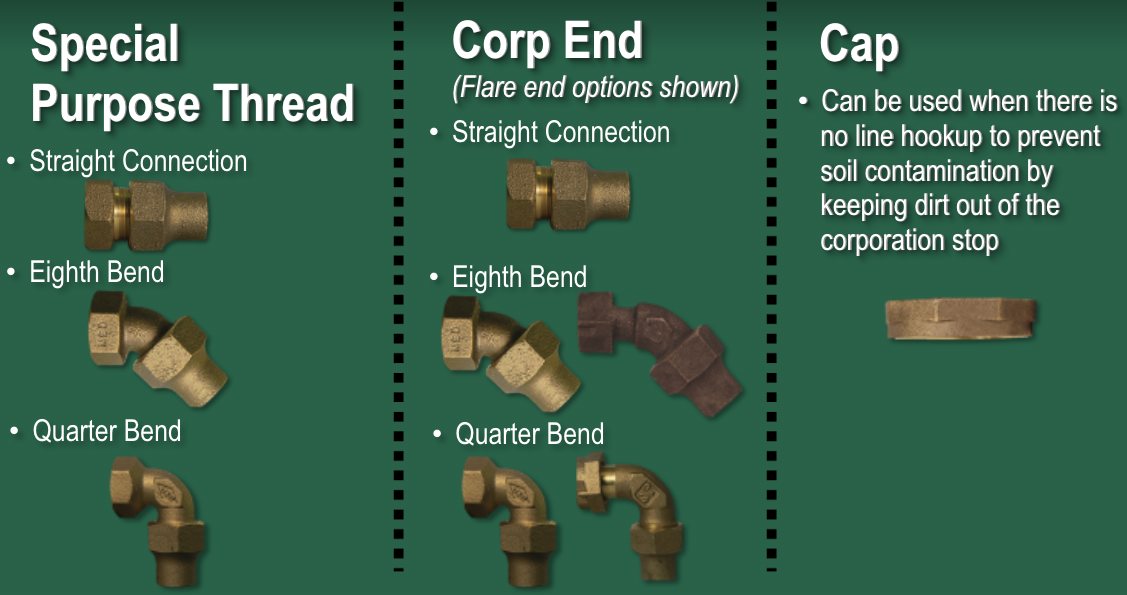

- Inlet tapered threads – NPT or AWWA

- Outlet tapered threads – FNPT or MNPT

- Outlet straight threads – Compression, Flare, or special purpose

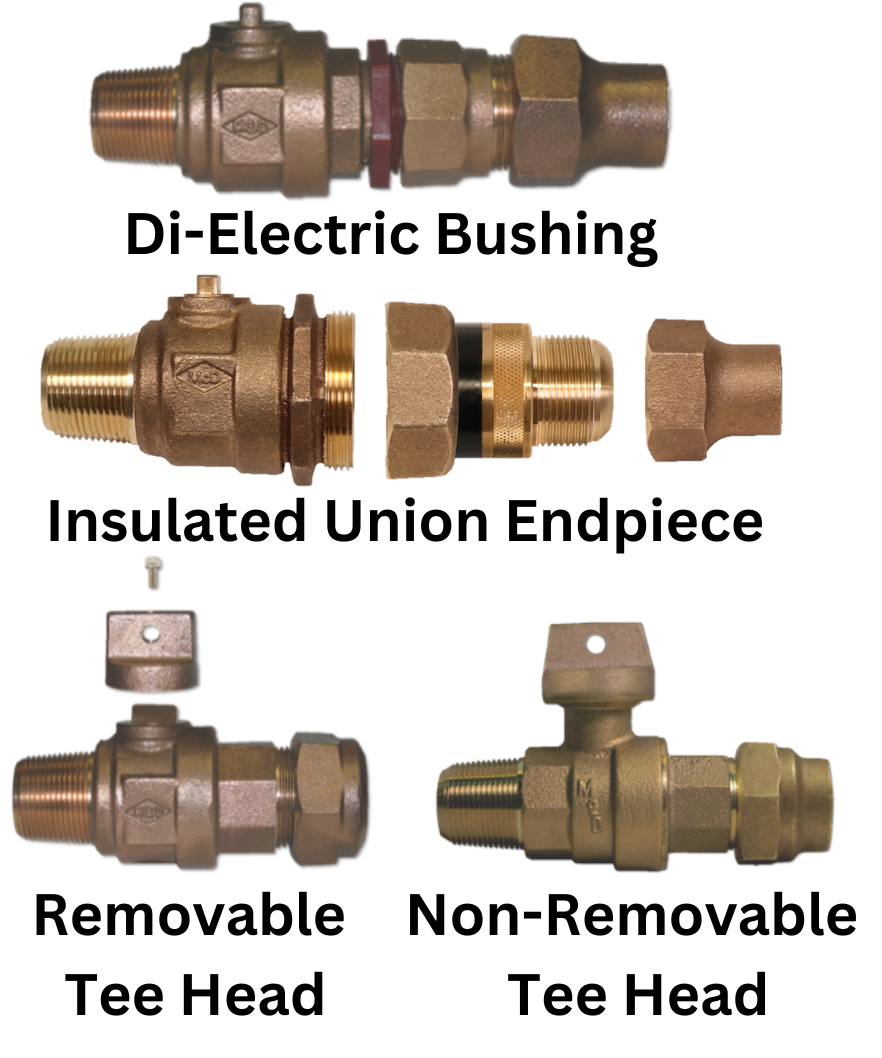

Corporation stops may include special features such as a di-electric bushing that helps prevent electrolysis and corrosion, as well as an insulated union endpiece. In addition, a removable and non-removable tee head option is available. Adapters are also an option and can have all the same outlet options as the corporation stop. Below are the options available:

As previously mentioned, corporation stops can be ball or plug. Below are how they compare:

Ball:

- 360-degree operating head

- Contains a ball supported by rubber or Teflon seals. Some manufactures utilize a single rubber seal design.

- Lower turning torque than plug valves

- Pressure rating range of up to 300 PSIG

- Rubber O-ring(s) in the stem assures a watertight seal to the atmosphere

Plug:

- 360-degree operating head

- Held in place using a D-washer and a nut

- Factory assembled and the nut should NOT be adjusted in the field

- Lubricant creates a watertight seal between the plug and body and allows the valve to be opened and closed

- Normal pressure classification per ANSI/AWWA C800:

- 1/2”, 5/8”, 3/4”, and 1” valves – 100 PSIG at 100F

- 1 1/4”, 1 1/2”, and 2” valves – 80 PSIG at 100F

The proper installation of a corporation stop includes requirements per ANSI/AWWA C800 regarding drill size and corp dimensions. To learn more about the requirements surrounding the design and installation of this part, take the ‘Corporation Stop Requirements’ A.Y. McDonald University (AYU) course, call our customer service department at 1-800-292-2737, or fill out a Contact Us page on aymcdonald.com