How A.Y. Ensures a High-Quality Gas Product

How A.Y. McDonald Ensures a High-Quality Natural Gas Product

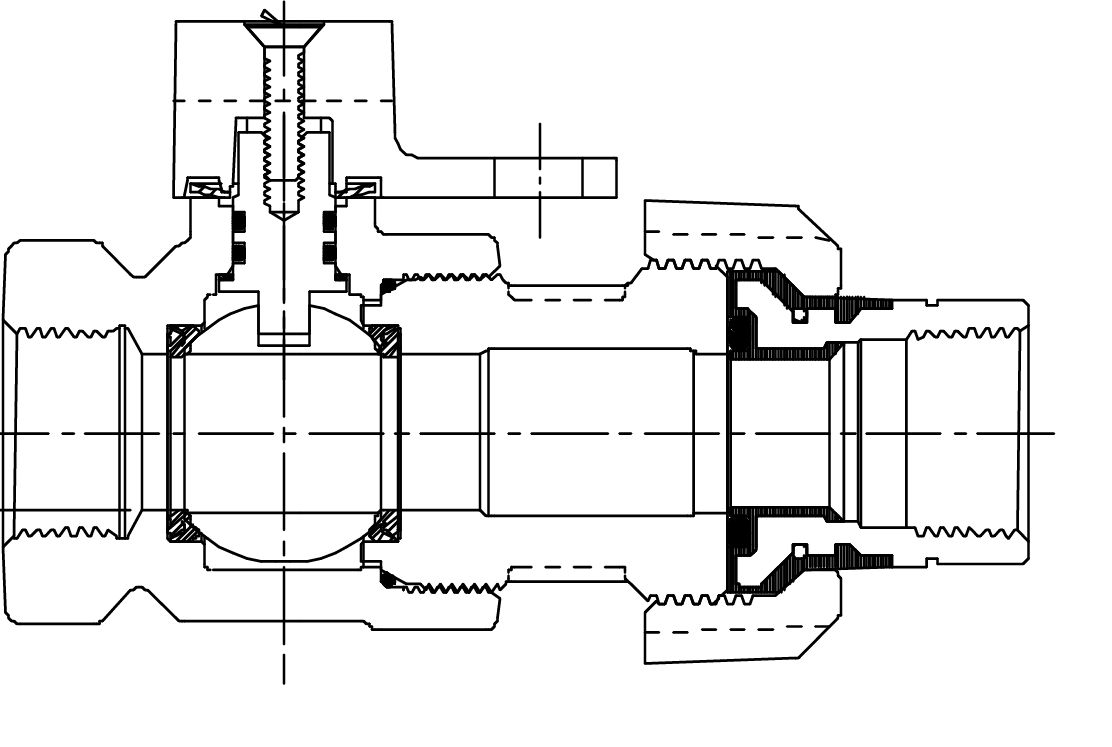

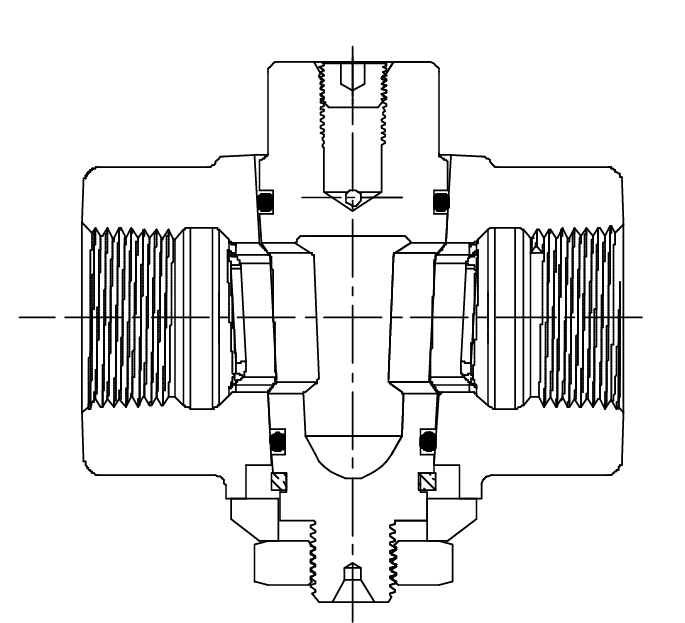

When dealing with natural gas, safety is always a top concern. The purpose of the natural gas meter set is to provide a home or building access to this resource in a safe and efficient manner. The meter set includes many parts, such as natural gas valves and meter bars. These important devices help control the flow of gas during normal use and maintenance.

For a manufacturer, creating a quality solution is a priority throughout the entire production process, starting with sand casting. The sand casting process for natural gas valves includes the following steps:

- The sand is mixed with clay and water

- A machine squeezes the sand around the pattern to make a mold

- The metal is poured into the mold to make the casting

- The castings go through a cleaning process to remove sand

After the cast has been made, quality continues to be a top priority during the manufacturing process for both valves and bars. Continue reading to find out what quality measures are taken throughout the rest of the production journey.

- Manufacturing Equipment

Maintaining a high-quality product is a very large factor to manufacturing iron and brass castings. Doing so includes checking the chemistry of the metal with a spectrometer as well as instruments that are used to measure the tensile strength and hardness of the castings. Coatings are used to further ensure a high-quality product.

Gas components have tight dimensional tolerances so precision measuring devices are used to measure them during production. These critical dimensions are measured by CMM, calipers, height gauges, or specialty functional gauges.

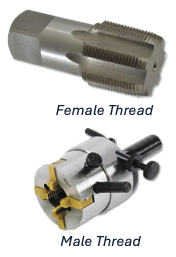

- Threads

Thread gages are used to check tapered threads, as well as straight threads. For straight threads, Go and No-Go ring gages check external threads while Go and No-Go plug gages check the internal threads. A series of ANPT (Aeronautical National Pipe Taper) gages are used when checking male and female NPT (National Pipe Thread) threads.

- Pressure Testing

The B16.33 standard requires all valves to be tested at one and a half times the rated pressure. This testing can be done by either using electronic pressure testing or by pressurizing the part while it is underwater and looking for bubbles. The valves are tested in the closed position and in the open position. Similar testing practices as the valves are used to test the bars but, since the bars are after the regulator, testing at the factory exceeds 1 ½ times the rated pressure.

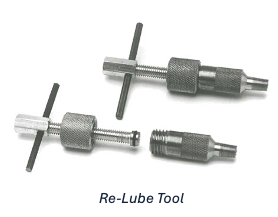

- Re-Lube Feature

Some plug style valves are created with a re-lube feature which allows fresh grease to be pumped into the valve. This is a useful feature if the grease dries out, is blown off the plug, or it the valve starts leaking for some reason. The re-lube ports may be in the head of the plug or in the side of the body, depending upon the manufacturer of the valve.