A.Y. McDonald Water Works Check Valves and Backflow Prevention

A.Y. McDonald Water Works Check Valves and Backflow Prevention

Protecting our drinking water supply is a top priority for water providers. Therefore, as the industry continues to improve, so do the products that transfer this resource from the water supply to the water meter. One of the ways in which this is achieved is through backflow prevention.

In relation to the water and plumbing system, backflow is the unwanted flow of water in the reverse direction. This can lead to the contamination of potable water supplies with foul water. Backflow may occur from one of two reasons:

- Back pressure: The result of a higher pressure in the system than in its supply. For example, if the system pressure has been increased by some means. This can happen in unvented heating systems where thermal expansion increases the pressure.

- Back siphonage: The result of supply pressure being lowered below that of the system. This can happen when a supply is interrupted or drained down.

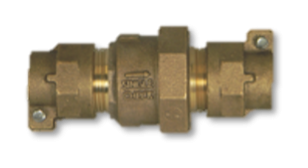

Although there are many types of check valves in use today, the most common are the spring assisted in-line and angle, single, and double check valve. Other common check valve types include ball, dual plate or double-door, piston or lift, and swing or flapper. Common materials used are brass, stainless-steel, steel, and PVC. A.Y. McDonald water work valves are constructed of brass and include a variety of configurations and applications. Below is an overview of our water works check valve product options:

|

Name of |

Description of |

Picture of |

|

701 and 7101 Inline Single |

- Available with a wide variety of threaded or compression connections |

|

|

702 Angle Single |

- Available with a wide variety of threaded or compression connections |

|

|

711 Inline Dual |

- Available with a wide variety of end connections to connect directly to water meters and/or other types of piping |

|

|

711X Inline Dual |

- Reduced weight check valve when compared to the 711 series |

|

|

712 Angle Dual |

- Available with a wide variety of threaded, oval meter flange, or compression connections |

|

|

7111 Inline Accessible Dual |

- Available with a wide variety of threaded or compression connections |

|

|

7112 Angle Dual |

- Available with a wide variety of threaded or compression connections |

|

|

7312 Angle Cascading Dual |

- Available with a meter swivel nut inlet and FNPT outlet configuration |

|

|

7411 Inline Y Pattern Cascading Dual |

- Available with a wide variety of threaded or compression connections |

|

The backflow of water and the steps to prevent it is a hot topic in the water industry. Thankfully, check valves serve as a possible solution due to their ability to the unique design of the one-way valve. To learn more about water works check valves and how to order an A.Y. McDonald water works check valve product option, take the ‘A.Y. McDonald Water Works Check Valves’ AYU course, call our customer service department at 1-800-292-2737 or fill out a contact us form on our aymcdonald.com website.