How to Check the Shaft Height of a Submersible Pump Motor

How to Check the Shaft Height of a Submersible Pump Motor

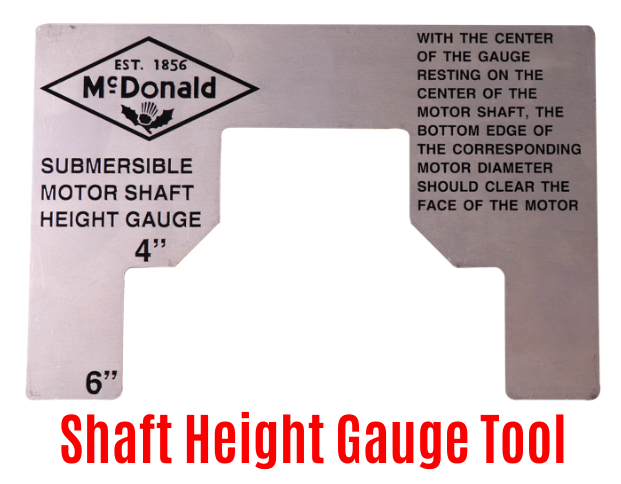

The three basic components of a submersible pump include the pump end, motor, and control box (three wire only). When one of these components becomes faulty, this means that the pumping system doesn’t perform as efficiently, thus lowering the lifespan of the pump itself. One way in which to test if the motor is up to par is by utilizing a shaft height gauge tool.

Due to the construction and operation of submersible pump ends and motors, there can be a high axial load placed on the rotor of the motor. This fact necessitates a special type of bearing, called the thrust bearing. The thrust bearing typically used on a 4” submersible motor is called a Kingsbury type, which is dependent upon a thin film of fluid between the shoes and the thrust plate to support the rotation parts of the motor and to carry the total thrust load exerted by the pump.

Because the thrust bearing can have an impact on the spacing of the pump’s impellers, it is height critical. If just a thin layer of material is burned off, then not only is the bearing damaged but it may cause rubbing of the impellers. The following scenarios can cause damage to a motor’s thrust bearing:

Damaged in shipping – motor could have been dropped or mishandled

- Overheated due to excessive number of starts

- Improper motor orientation (minimum 30-degree angle recommended)

- Improperly sized for the application

The shaft height gauge tool can be utilized by placing the tool so that it rests on top of the motor (see picture to the right). Based off of where it lies on the shaft and motor shell, this will indicate a pass or fail for the motor due to a defective thrust bearing. The following scenarios would indicate a normal, low, or high shaft height based off of the behavior of the shaft height gauge tool:

- A normal shaft height means the tool rests on the shaft and swings freely above the motor shell. This indicates the pump is ready to use.

- A low shaft height means the tool rests on the shell and swings freely above the shaft. The thrust bearing is possibly damaged and the motor should be replaced.

- A high shaft height means the tool floats and does not contact the motor shell (gap of >.04 for A.Y. McDonald submersible motors). The motor will likely not fit on the pump properly and will not perform to the expected specifications.

The submersible motor not only drives the pump but the horsepower of this component, matched with the pump, also determines the pressure and gallons per minute provided by the well system. Based off of its importance to the function of the pump, it is pertinent that the motor is operating efficiently – and the shaft height gauge tool is a simple way in which to test this fact. For more information on the background of this tool and how to determine the results, take the ‘Checking the Shaft Height of a Submersible Motor’ AYU course.