The Importance of a Pressure Tank

The Importance of a Pressure Tank

When you open a spigot in a home or building, you expect water to flow at a certain pressure. This flow is determined by the water pressure in the line. How water pressure is controlled within a structure greatly depends on how this resource is obtained. With city utilities, water pressure is controlled, for the most part, by the city. With water wells, a pressure tank is necessary in order to build the proper amount of pressure.

For a water well, the combination of the pressure tank, pressure switch, and pump allow water to flow through a structure. As one of the main components to a pump system, the pressure tank allows the following:

- Protects and extends the life of a pump by reducing the number of cycles

- Provides storage of water under pressure for delivery between cycles

- Reserves capacity for periods of peak demand

- Reduces system maintenance

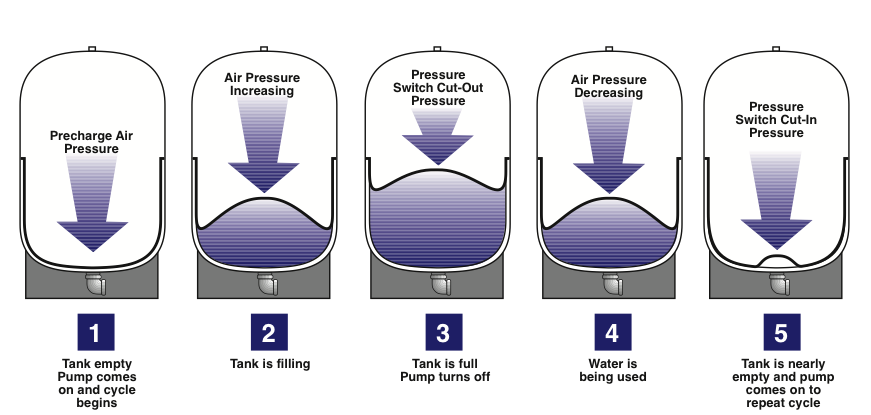

The pressure tank in a water well system creates water pressure by using compressed air to push down the water in the tank. Due to this pressure, water is pushed out of the tank through the pipes in your home when a valve is opened. A pressure switch is activated when the water in the pressure tank drops below the minimum pressure setting. This turns the pump on so that the pressure tank can be refilled.

Pressure tanks are generally set to keep pressure within 20 pounds per square inch (PSI) of your starting and stopping parameters. For example, most homes have pressure of 40 PSI to 60 PSI. If the pressure drops below 40 PSI, the pump turns on and brings the pressure back to 60 PSI before turning off again.

Basic types of pressure storage tank designs include diaphragm or bladder tanks with permanent separation between air and water, tanks with a floating wafer separating air and water, and plain steel tanks. As the most common design, A.Y. McDonald DuraMAC™ pressure tanks are considered precharged diaphragm/bladder tanks. These function with the help of four cycles, which include the following:

- Start-up cycle: With the chamber empty, the diaphragm is pressed against the bottom of chamber

- Fill cycle: As water is pumped into the water chamber, the diaphragm is forced upward into the air chamber

- Hold cycle: When pressure in the air chamber reaches the pump cut-off point, the diaphragm is in the uppermost position and the water chamber is filled to operate capacity

- Delivery cycle: When water is delivered to the system, the pump remains shut off. Air pressure in the top of the chamber forces the diaphragm downward.

A.Y. McDonald DuraMAC™ pressure tanks contain free standing and in-line models with sizes 2 through 119 gallons. With pressure up to 100 PSI, our pressure tanks also come with a conveniently located air charge valve for easy pressure adjustment, a designer finish that ensures for a long-lasting solution, and a plastic lining that is permanently bonded to the shell in a two-coat base on epoxy lining. In addition, the tank construction is pre-pressurized at 38 PSI, includes lightweight drawn-steel construction, and is slotted and notched for air flow, reducing condensation build-up.

A water well’s pressure tank contributes greatly to the overall longevity and efficiency of the system. By better understanding how this part functions and why, you can also better grasp the importance of a high-quality pressure tank for any application. The next time you turn on a faucet, take a moment to recognize all the components it takes to successfully bring access of water to your home!

For more information on the topic, take the ‘Pressure Tanks’ AYU course.